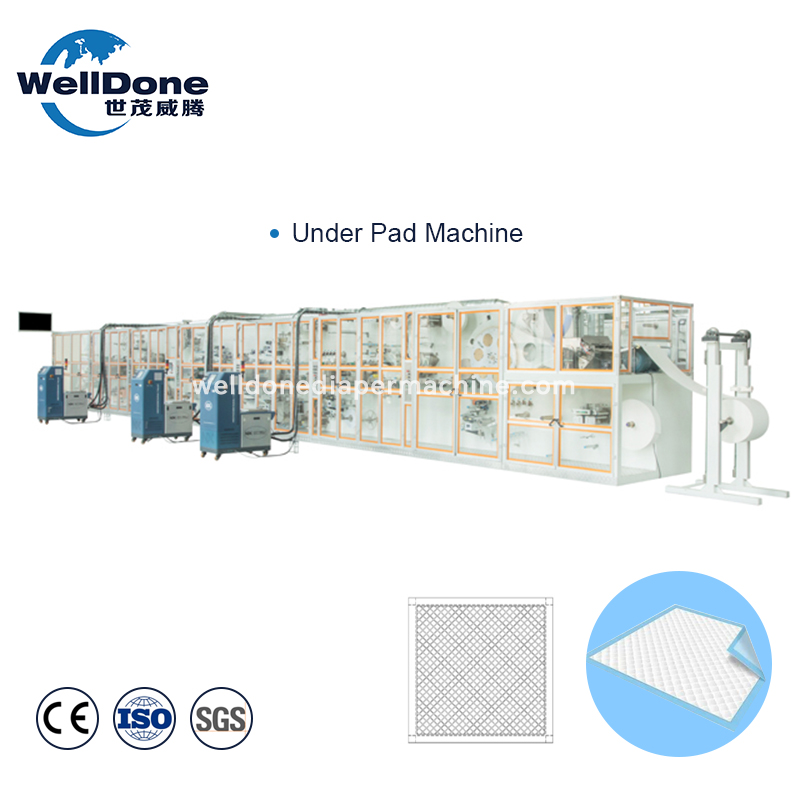

Professional Full servo Under Pad Production Line manufacturers

Welldone Under pad machine has modular structure, easy operation and maintenance, while the system can be updated for customer’s reasonable requirement. Machine is designed under CE standard and approved by CE license, while the electric parts are with CE certificate already. Safety door and emergency stop button are mounted also. Interface adopted specialized industrial computer, humanized design and easy control, real-time data collection and alarm warning. Machine has relative defects auto rejecting.

- Introduction

Introduction

Description:

Welldone Under pad machine has modular structure, easy operation and maintenance, while the system can be updated for customer’s reasonable requirement. Machine is designed under CE standard and approved by CE license, while the electric parts are with CE certificate already. Safety door and emergency stop button are mounted also. Interface adopted specialized industrial computer, humanized design and easy control, real-time data collection and alarm warning. Machine has relative defects auto rejecting.

Specifications:

| ble Industries | Hygiene Product Manufacturing Plant | Showroom Location | Egypt, Turkey, Philippines, Indonesia, India, Thailand, Kenya, Nigeria, Uzbekistan |

| Condition | New | Product Type | Paper Product Making Machinery |

| Processing Type | Laminating Machine | Place of Origin | Fujian |

| Brand Name | Welldone | Voltage | 380V 50HZ |

| Power | 220KW | Dimension(L*W*H) | 28.0m× 7.0m× 3.5m |

| Weight | 40T | Warranty | 1 Year |

| Production Capacity | 120Days average | After Warranty Service | Video technical support, Online support, Spare parts |

| Local Service Location | Egypt, Turkey, Russia, Spain, Malaysia, Kenya, Argentina, Sri Lanka, Kyrgyzstan | Certification | CE & ISO9001 |

| After-sales Service Provided | Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support, Engineers available to service machinery overseas | Name | High speed 600 pcs per minutes diaper manufacturing machine |

| Model | WD-UPM011 | Finished Products | Under Pad |

| Color | Customized | Manufacture Time | 120Days average |

| Raw materials | Wood Pulp/PE Film / SAP | place of origin | Fujian |

| Waste Rate | Less than 2% | Operators | 8-10 |

Quick Detail:

| Product type | Under pad |

| Design speed | 250m/min |

| Stable speed | 200-240m/min |

| Machine System(For new machine) | Customized Option A: Mitsubish Option B: Simons |

| Glue machine | Customized Option A: Chinese glue machine(Cost-effective) Option B: Nordson machine |

| Web guide | Customized Option A: Chinese web guide Option B: BST web guide(or other brand) |

| Passing rate | ≥ 98% (Not include the glue applicator, Auto Splicing) |

| Electric wire | 3×120mm2+1×50mm2+1×25mm2 |

| Compressed Air supply | 0.6-0.8Mpa |

| Working space | 39m*9m*5m(L*W*H) |

Parts Details:

Work Shop:

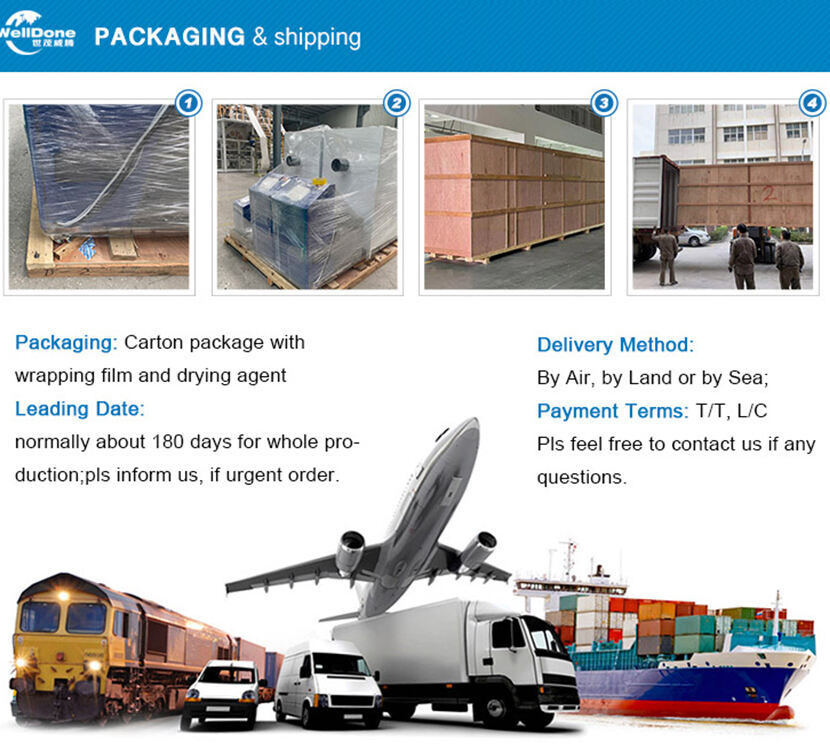

Machine Packaging:

Machine Packaging:

FAQ:

Q: How many years has your company been on the market?

A: We are focus on this hygiene industry filed already 15 years since 2008.

Q: What is the annual sales volume?

A: Usually our machine sales volume reach RMB100,000,000.00 it is about 20-25 sets machines each year, for another parts raw materials sales amount is about 80 million.

Q: Is there a quality management system such as ISO 9001?

A: We have approved ISO 9001 and CE Certification.

Q: Do you provide after-sales service support to suppliers?

A: Welldone Service Range:

1. Finished Product Design -Recommend suitable& competitive machine

2. Complete Hygiene Industry Management System Service:

A. Cost and Feasability Study

B. ROI (Return of Investment) Report

C. Production Factory Layout Plan

D. Material Planning Management

E. Warehousing Management Programs

F. After sales Service:

a. Installation service, b. operating machine, c. production team arrangement, d. non-scheduled service as per your requirement.

G. Quality Control System

H. Mechanical Failure Analysis System

I. Financial Analysis Programs for executive level

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

SR

SR

SK

SK

UK

UK

VI

VI

SQ

SQ

MT

MT

TH

TH

TR

TR

MS

MS

BE

BE

AZ

AZ

EU

EU

BN

BN

BS

BS

NE

NE

KK

KK

SU

SU

UZ

UZ

KY

KY

FY

FY

XH

XH