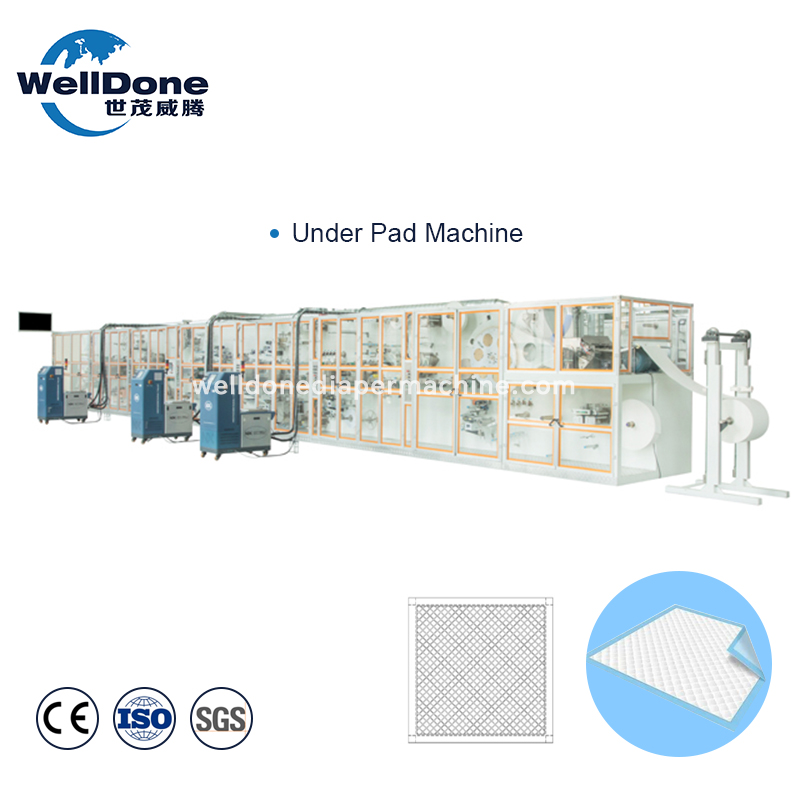

প্যাড তৈরি মেশিনটি অনেক অংশের স্মার্ট সংমিশ্রণ। প্রধান অংশগুলির মধ্যে রয়েছে ম্যাটেরিয়াল চালানোর জন্য কনভেয়র বেল্ট, যা ম্যাটেরিয়ালকে কাটতে সাহায্য করে এবং প্যাডগুলিকে সুন্দরভাবে ফোল্ড করে দেয়। প্রতিটি অংশই তার নিজস্ব কাজ পালন করে মেশিনকে সময়মত এবং দক্ষতার সাথে প্যাড উৎপাদনে সহায়তা করতে।

মহিলাদের স্বাস্থ্যসুবিধা সমগ্রভাবে প্যাড তৈরি করার মেশিনের কারণে উন্নয়ন লাভ করেছে, এটি প্যাড তৈরির নতুন উপায় তৈরি করেছে। এই মেশিন তৈরি হওয়া পর্যন্ত প্যাডগুলি হাতে তৈরি হত। এর অর্থ ছিল প্যাডগুলির প্রত্যেকটি বিশেষ হতে পারে, এবং তারা সমান আকার বা বেধের সাথে তৈরি হত না। কিছু খুব পাতলা এবং অপরিপূর্ণ হতে পারে, অন্যদিকে বাকি গুলি খুবই বেধা হতে পারে।

প্যাড তৈরি করা হয়েছে এমনভাবে যেন এগুলি বড় পরিমাণে একই রকম হয় প্যাড তৈরি করার মেশিনের মাধ্যমে। এর অর্থ হল মহিলাদের ও ছেলেদের মাসিক চক্রের সময় তারা পরিষ্কার, স্বাস্থ্যবান (কোনো সংক্রমণ পাওয়ার ঝুঁকি নেই) এবং আরও নিরাপদ থাকতে পারে। মহিলারা তাদের বিশ্বাস রাখতে পারে যে প্রতি বার তারা যখন প্যাডটি ব্যবহার করবে, তখন এটি কাজের জন্য কার্যকর হবে এবং তাদেরকে মাসিক চক্রের সময় অসুবিধা দিবে না।

অধিকাংশ উন্নয়নশীল দেশে মহিলাদের ও ছেলেদের জন্য প্যাডের অভাব রয়েছে। এই সুযোগের অভাব তাদের জন্য গুরুতর বাধা তৈরি করতে পারে যা তাদের শিক্ষা বা কাজের সাথে সম্পর্কিত হতে পারে মাসিক চক্রের ব্যয়ে। মাসিক চক্র পরিচালনা করতে না পারার কারণে ছেলেরা শিক্ষালয়ের শ্রেণিকক্ষে গুরুত্বপূর্ণ শিক্ষা হারায় এবং কিছু ক্ষেত্রে তারা সম্পূর্ণভাবে শিক্ষালয় ত্যাগ করতে পারে। প্যাড তৈরি করার মেশিন এই সমস্যাটি সমাধান করছে স্থানীয়ভাবে তৈরি প্যাডের মাধ্যমে।

তেমন ধরনের জাতিগোষ্ঠীতে কিছু সংগঠন এবং সমাবেশ প্যাড তৈরির যন্ত্রপাতি প্রদান করছে, যা তাদের মধ্যে সাধারণ অকৌশলীয় ব্যক্তিদের জন্য চাকরি তৈরি করে এবং মহিলাদের ও ছোট মেয়েদের দ্বারা সস্তা প্যাড তৈরি করার সুযোগ দেয়। এছাড়াও মাসিক ধারণা শুচির উন্নয়ন এবং অর্থনীতিকে সমর্থন করে। যখন মহিলাদের এবং মেয়েদের প্রয়োজনীয় প্যাডের সহজ প্রবেশ থাকে, তখন তারা চিন্তা বা লজ্জা ছাড়াই তাদের দিন কাটাতে পারে - শিক্ষা, কাজ এবং মর্যাদা তাদের সীমান্তে আসে।

প্যাড তৈরির যন্ত্রের কাজ: প্যাড তৈরির কাজের শৈলী খুবই আকর্ষণীয় যেহেতু এটি কোনো কঠিন হাতের শক্তি ব্যবহার না করে প্রোডাকশন করে। প্রথমে আপনার প্রয়োজন হবে একটি বড় রোল সpong উপাদান যা প্যাডের জন্য মূল উপাদান হিসেবে কাজ করে। এই পয়েন্টে, রোলটি একটি কনভেয়ার বেল্টে স্থাপন করা হয় যা যন্ত্রটির মাধ্যমে উপাদানটি চালায়। তারপর কাটিং ব্লেডগুলি উপাদানটিকে আকার অনুযায়ী কাটে এবং প্রতিটি প্যাডকে আলাদা করে।

তারপর ফোল্ডিং মেশিনটি সঠিকভাবেই প্রতিটি প্যাডকে অর्धেক করে ভাগ করে প্যাকেজিং জন্য। তারপর প্যাডগুলি ফোল্ড হয়, একটি সুন্দর প্যাকেজে প্যাক করা হয় এবং বিতরণের জন্য প্রস্তুত। শুরু থেকেই এটি অবিশ্বাস্য মনে হয়েছে যে এই প্যাড তৈরি মেশিনটি কতটা দক্ষ তা কল্পনা করা, যা কিছু ঘণ্টার মধ্যে চোখ কপটেই হাজারো প্যাড তৈরি করতে পারে! এই পরিমাণের উৎপাদন হল অনেক মহিলা এবং মেয়েদের নিয়মিতভাবে প্যাডের সুবিধা পাওয়ার একমাত্র উপায়।

আমাদের প্যাড তৈরি মেশিন কেনা করার পরে তা শুধু উচ্চ-পারফরম্যান্স নয়, তবে এটি আপনাকে আঞ্চলিক তেথনিক্যাল সাপোর্টও দেয়। আপনি সমন্বয় এবং বর্তমান ফিরিয়ে আনুন যা আপনার উৎপাদনশীলতা এবং বৃদ্ধি বাড়াবে

আমাদের মিল প্যাড তৈরি মেশিন সরঞ্জামের জন্য যা ১৯৯৬ সাল থেকে ইঞ্চ মেথড কারণ যা এবং একটি দল কার্ডিনাল দেশ বিক্রয় ব্যক্তিগত পিছনে ইঞ্চ কার্ডিনাল ভিন্ন ভাষায়। এটি নিশ্চিত করে যে আপনি যে কোনও বাজারে সফল হবেন।

আমাদের প্যাড তৈরি মেশিন হল একটি নিরাপদ এবং কার্যকর বিশ্বব্যাপী সমাধান যা প্রতি বছর ৮০০ টি বেশি কনটেইনার একспор্ট করতে পারে। আপনার লাইন যেখানেই নিয়ে যায়, আমাদের পণ্যগুলি আপনার আশা পূরণের জন্য উপযুক্ত।

আমাদের পক্ষ প্যাড তৈরি মেশিনের একটি ব্যাপক বৈচিত্র্য প্রস্তাব করে যা প্রথম থেকেই পরবর্তী দেখাশোনা পর্যন্ত সহায়তা করে। আমরা আপনার সatisfaction নিশ্চিত করতে নির্দিষ্ট যে আপনি আপনার বিনিয়োগ থেকে সর্বাধিক উপকার পাচ্ছেন। অভিনবতার উপর ভিত্তি করে উত্তর দেওয়ার দিকে ফোকাস করে এবং এলাকায় কয়েক বছরের অভিজ্ঞতা সঙ্গে, আমরা আমাদের পণ্যগুলি এগিয়ে নিতে প্রস্তুত যেন বাজারের সবচেয়ে আগে থাকে। আমাদের সাথে যোগদান করুন যেন একটি সতত পরিবর্তিত বাজারের আগে থাকতে পারেন।

আমাদের পেশাদার বিক্রয় দল আপনার পরামর্শের জন্য অপেক্ষা করছে।