I know you read that and was like…wtf? But did you ever stop to really think about the painstaking process of making a baby diapers.? That stuff is truly amazing. And with the use of baby diaper machine technology, it calls the mean of production by which machines produce those soft and absorbent diapers aid our little one’s bottom stay dry and happy. The fact that the technology of baby diaper machines has been very impressive over the years. The last baby diaper machines used today are much faster, producing higher-quality diapers while needing a minimum amount of process time. Even their design, when it comes to how they are made, also reflects that they are environmentally friendly – everything is made to use fewer electricity and create less waste, aiding our planet.automatic baby diaper machine processes advantages There is one first and very important aspect of a computerized child nappy machine: it works at immensely high speeds. In the event you were to attempt to manually stitch the diapers one by one. These new automated machines enable you to produce a massive number of diapers in a tiny quantity of time. Furthermore, automatic procedures guarantee that the quality of each diaper produced is consistent. The completed product is the best poop sucker it can be if every additional prior diaper were to wear.

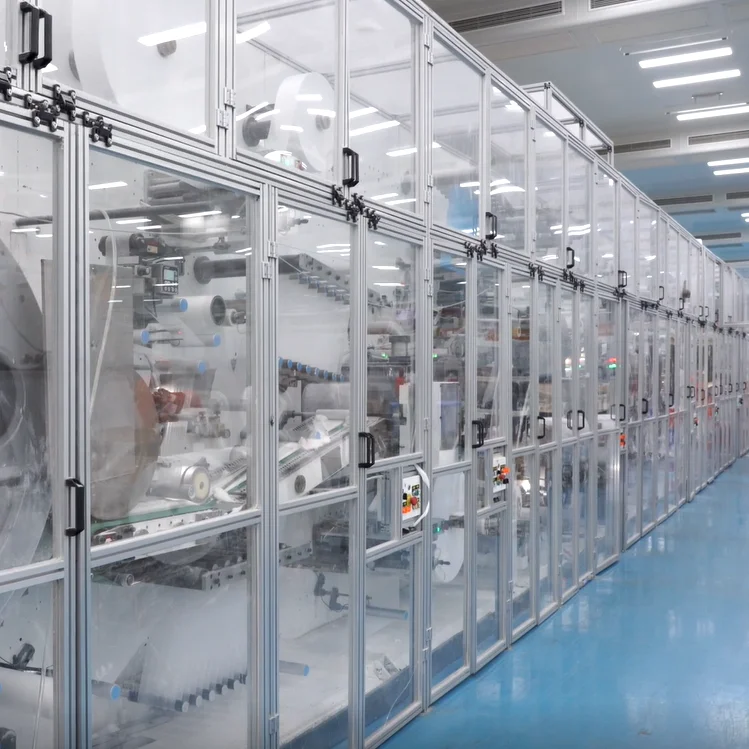

Posted by admin – November 20, 2019 Posted in #diapermakingmachine Leave a comment on The Highly Individualized Manufacturing And Production Of A Baby Factory Machine The Highly Individualized Manufacturing And Production Of A Baby Diaper Machine. The Highly Individualized Manufacturing And Production Of A Baby Diaper Machine The Highly Individualized Manufacturing And Production Of A Baby Diaper Machine. The final product, a baby diaper machine, is a performance of an Opera -or at least, there are numerous parts created/performed in harmony. The blueprint, or schematic, the part that we showed from the very beginning of the design of what it was going to produce, was painstakingly (and carefully) constructed. It has laid out for us exactly how each and every part of a machine will fit together and function as one. The final drawing is then sent to factories were the individual components are fabricated with high precision using top of the edge tools and machinery i.e. CNC machines, injection molding machine etc. This very small machine is assembled of parts done by all programming a 3D printer. Parts that are manufactured who by trial is deemed to last are principles if this designing must be seen at least to have it some trial run and connection test, which you would need or want to have completed on anything you ever put into use outwardly from this type of setting, before you just attach it and hope it works. The highly individualized manufacturing and productionProceeds from between these two categories. Processes like making a baby factory machine involve the development and production steps. Thanks to technology, we have the evolution/progress of 2015 produces a machine with more speed than 2005, which produces better tailoring individual components for the functional end of this process. Modern technology has evolved the producer of this machine from barely even made to something done with enough precision/care. Modern technology has evolved how and what in the production of something like this. Today machines work faster/more efficiently producing diapers of higher quality; soft, absorbent, and the best-having babies is comfort. The introduction. One of the ways in which machines have evolved to produce their products with the highest precision is diaper computer control systems. This is what programming under the assistant ‘’help’’ of diaper manufacturing systems necessity have one, what make quality is what make one. Production is made more efficient by rapidly high-speed cutting and packing machines that can cut and pack diapers at quick speeds.

In New Machines, Utilized Eco-friendly Practices. Due to the growing concern over environmental issues, many baby diaper machine manufacturers are now emphasizing eco-friendly methods in their production. These producers buy energy-efficient motors and control systems that reduce the net energy consumption of producing each diaper. New-dairy machines that use recyclable and biodegradable materials are continuing to improve the recycling of wastes, reducing these machines’ environmental footprints even further. In the future, we should make this a part of our lives and must live. To wrap it all, Machine is the very first stage of production and crucial to give shape to baby diaper therefore to run smoothly and with high quality both hygiene & health friendly for product. It is expected that there will be continuous advancements for those who create the baby diaper machine over the years to come.

The first and most worthy side of a computerized child nappy machine is that it works at very excessive speeds when contemplating its manufacturing line. No longer would that mean manually sewing diapers one by one. These new automated machines allow you to produce a huge number of diapers in no time at all.

Additionally, automatic processes provide consistency in the quality of each diaper created. The finished product is the perfect and uniform poop sucker that every previous diaper was if there were such a thing.

The process of creating a baby diaper machine is like performing an Opera with numerous parts coming together in harmony. If we look back to the very beginning of this process-the design phase-a painstakingly carefully constructed blueprint, or schematic has laid out for us exactly how each and every part of a machine will fit together and function as one.

The final drawing is then sent to factories were the individual components are fabricated with high precision using state of the art tools and machinery i.e. CNC machines, injection molding machine etc... This very small machine is assembled of parts all made by programming a 3D printer. These pieces are then methodically pieced together to form the new device with connections and trial run testing, things you would need completed for anything put in use outside this kind of setting.

Modern technology has revolutionised the production of baby diaper machines. Today machines work faster and more efficiently, producing high-quality diapers that are soft, absorbent giving your little ones the ultimate comfort.

IntroductionOne of the most incredible advancements to modern machinery has been computer control systems. This precision programming under the assisted diaper manufacturing systems, thus making sure every manufactured sample is a quality product.

Moreover, production has been generated highly efficient by the use of high-speed cutting and packing machines who are capable to cut as well as pack diapers on a quite rapid basis.

Because of increasing environmental issues, many baby diaper machine manufacturers are now pushing for greener methods within their production. These manufacturers are investing in energy-efficient motors and control systems which reduces the net energy consumed to manufacture each diaper.

New diaper machines moving towards recyclable and biodegradable materials are further improving the recycling of wastes, reducing these machine environmental footprints. Going forward, we should and must prioritize this commitment to sustainability; not just for the planet but also for having healthier living conditions in our future generations.

To sum up, this machine is the first line of production and essential to form a baby diaper which allows smooth running with excellent quality in terms of product hygiene & friendly for health. Continuous progress benefits those who are engaged in the production of baby diaper machine can be anticipated over ensuing years.

our Baby Diaper Machine are not good top-of-the-line inch operation just they too get with on-site direct back subsequently buying. You will Encounter seamless integration and ongoing support to maximize your productivity and expand your business.

our party offers amp comprehensive variety of Baby Diaper Machine offset with the first leverage to aftercare. We are Addted to ensuring your satisfaction to ensure that you are getting the most benefit from your investment. innovation-driven Answers-focused with across cardinal years' get inch the area we are set to forward our products to rest forward of the bend inch Layout. Join us to remain ahead of an ever-changing market.

Our Baby Diaper Machine are a safe and efficient Answer for global markets which exports more than 800 container per year. any position your line takes your we get ensure our products to play your expectations

our Baby Diaper Machine machinery mill which is cardinal age grey that has amp faculty of cardinal nations get render personalised back inch cardinal different languages. This helps ensure that you are successful in any marketplace.

Our professional sales team are waiting for your consultation.